Titanium Zirconium Nickel Hastelloy Storage Tank Tower Mixer Pressure Vessel

Basic Info

| Model NO. | Pressure Vessel |

| After-sales Service | Technical Consulting,Technical Support Online |

| Warranty | 365days |

| Function | Storage Pressure Vessel, Separation Pressure Vessel, Heat Pressure Vessel, Reaction Pressure Vessel |

| Application | as Requires |

| Material | Customized |

| Pressure | as Requires |

| Condition | New |

| Weight | Customized |

| Height | Customized |

| Modes of Transport | by Sea, Air Railway |

| Transport Package | Wooden Case/Container |

| Specification | 10L-100000L |

| Trademark | JINJIANTAIYE |

| Origin | China |

| HS Code | 73101000 |

Product Description

Product Description

What is a chemical storage tank?

A storage tank is a container that holds liquids, compressed gases, or mediums used for the short- or long-term storage of heat or cold. The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers.

Chemical reaction engineering is the branch of chemical engineering which deals with chemical reactors and their design, especially by the application of chemical kinetics to industrial systems.Storage tanks are available in many shapes: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom and dish bottom. Large tanks tend to be vertical cylindrical, or to have rounded corners transition from vertical side wall to bottom profile, to easier withstand hydraulic hydrostatically induced pressure of the contained liquid. Most container tanks for handling liquids during transportation are designed to handle varying degrees of pressure.

Applicable Industry

Tanks for a particular fluid are chosen according to the flash-point of that substance. Generally in refineries and especially for liquid fuels, there are fixed roof tanks, and floating roof tanks.

- Fixed roof tanks are meant for liquids with very high flash points, (e.g. fuel oil, water, bitumen etc.) Cone roofs, dome roofs and umbrella roofs are usual. These are insulated to prevent the clogging of certain materials, wherein the heat is provided by steam coils within the tanks. Dome roof tanks are meant for tanks having slightly higher storage pressure than that of the atmosphere (e.g. slop oil).

- Floating roof tanks are broadly divided into external floating roof tanks (usually called floating roof tanks: FR Tanks) and internal floating roof types (IFR Tanks).

IFR tanks are used for liquids with low flash-points (e.g., ATF, MS. gasoline, ethanol). These tanks are nothing but cone roof tanks with a floating roof inside which travels up and down along with the liquid level. This floating roof traps the vapor from low flash-point fuels. Floating roofs are supported with legs or cables on which they rest. FR tanks do not have a fixed roof (it is open in the top) and have a floating roof only. Medium flash point liquids such as naphtha, kerosene, diesel, and crude oil are stored in these tanks.

One of the best types found in mining areas is the open roof type tank, usually to store ore slurries. These are the easiest storage tanks to build.

Other classifications which can be made for storage tanks are based upon their location in a refinery:

- COT- crude oil tank-ages

- PIT- product and intermediate storage tankages

- DISPATCH- dispatch area tankages

- UTILITIES- tanks made in the power plant area, for storage water, etc.

- OSBL tanks- the first 3 types come under outside battery limit tankages

- ISBL tanks- these are usually mini tanks that are found in the production units of a refinery (as neutralization tanks, water tanks, etc.)

As flash-points of fuels go very low the tanks are usually spherical (known as spheres), to store LPG, hydrogen, hexane, nitrogen, oxygen, etc.

Product Parameters

| Specification for reactor | |

| Material | Carbon steel, Titanium, nickel, zirconium, Hastelloy (C-B), Monel and their composite materials, 316L / 304 / 2205 / super dual-phase steel, etc. |

| Sealing Method | Packing seal or mechanical seal (vacuum) |

| Installation type | Horizontal/Vertical |

| Carried standard | GBT151-2014 ASME ANSI |

| Remarks | We support OEM |

*All the types can be designed and customized. Contact me for more details

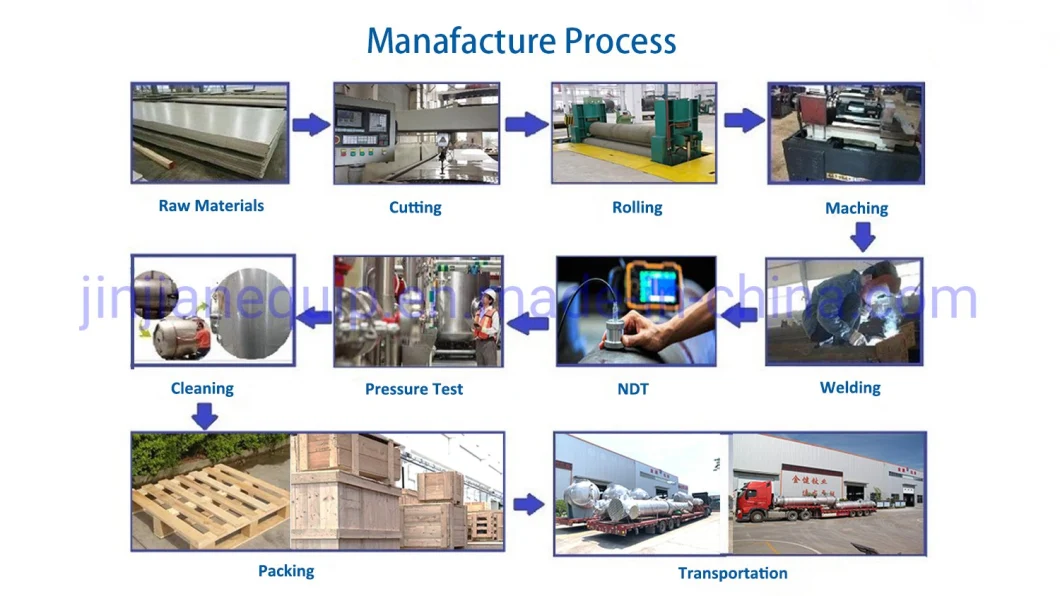

Manufacture Process

Company Profile

Weifang Jinjian Titanium Equipment was founded in 1996 as a high-tech enterprise with the highest A1 and A2 class pressure vessel manufacturing and design qualifications now. It is the earliest and largest manufacturer of special materials equipment in East China. As well as the base of special material equipment in China. Our company covers an area of 80000m², with 56000 m² of workshop area, 6000 m² of the warehouse area, and 600 m² of flaw detection room area. We have 46 engineers& technicians, 72 welders, for special pressure vessels. We have passed the ISO9001 / 14001 / 18000 certification. We have satisfied products, advanced detection measures, sound quality assurance systems, scientific management experience, a comfortable environment, and convenient transportation. We warmly welcome people with lofty ideals from all walks of life at home and abroad to guide us.

Packaging & Shipping

1. Carefully check the quantity and quality of equipment before packing.2. Good packed by plastic wrap.3. Iron Frame, Suitable for land transport and sea freight.4. Fittings and spare parts are packed in a wooden pallet.5. Add labels and shipping marks.

1. Delivery Terms: CIF, CFR, FOB, EXW, transport by air, by sea, by express DHL, FedEx, TNT, EMS, etc.

2. Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight, etc.

3. Minimum Order Quantity (MOQ): 1Ton or 100Pcs per size.

4. Carefully check the quantity and quality of equipment before packing.

5. Good packed by plastic wrap. Iron Frame, Suitable for land transport and sea freight.6. Fittings and spare parts are packed in wooden pallets.

7. Add labels and shipping marks.

Partners

1. Southeast Asia customers 2. Russian customers 3. German customers 4. Kazakhstan customers 5. American customers 6. European customers 7. Thailand customers 8. India customers 9. Vietnam customers 10. Middle East customers 11. India customers 12. Uzbekistan customers 13. Thailand customers 14. Ukraine customers 15. Russian customersFAQ

Q: Are you a manufacturer or a trader?

We're a manufacturer with more than years of professional production experience.

Q: Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

Q: Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

Q: Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

Q: What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

Q: How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.