Titanium Alloy Fittings

Basic Info

| Model NO. | KM-20200716 |

| Specification | 1/2 inch~24 inch |

| Trademark | Kingmetal |

| Origin | China |

| HS Code | 8108909000 |

| Production Capacity | 300 Tons Per Month |

Product Description

Titanium Alloy FittingsSeamless fittings: size from 1/2″ to 16″; wall thickness from SCH 5S to SCH 80S.

Welded fittings: size from 1/2″ to 24″; wall thickness from SCH 5S to SCH 80S.

The fittings shall be manufactured in accordance with the dimensional requirements of ASME B16.9 and MSS SP 43. And the material shall be furnished as stress-relieving annealed conditions.

Specification :

| Grades | Titanium GR-1 (UNS R50250) |

|---|---|

| Dimensions Std | ANSI/ASME B16.9, B16.28, MSS-SP-43. |

| Specifications | ASTM B 363 / ASME SB 363 |

| Size | ½" NB - 24" NB |

| Schedule | SCH 10 - SCH XXS |

| Type | Seamless / ERW / Welded / Fabricated |

Types of Buttweld Fittings :

| Titanium Reducers | Titanium Concentric Reducers | Titanium Tees |

| Titanium Weldolet | Titanium Short Stub End | Titanium Eccentric Reducers |

| Titanium Elbows | Titanium 3D Elbow | Titanium Lap Joint Stub End |

| Titanium End Caps | Titanium 5D Elbow | Titanium 180° SR Return Bends |

| Titanium Elbows | Titanium Short Radius Elbow | Titanium 45° Elbows |

| Titanium Reducing Elbow | Titanium Long Radius Elbow | Titanium 180° LR Return Bends |

| Titanium 45° Elbows | Titanium Equal Tee | Titanium UnEqual Tee |

| Titanium Reducing Tee | Titanium 1D Elbow | Titanium 1.5D Elbow |

| Titanium Long Stub Ends | Titanium 2D Elbow | Titanium 6D Elbow |

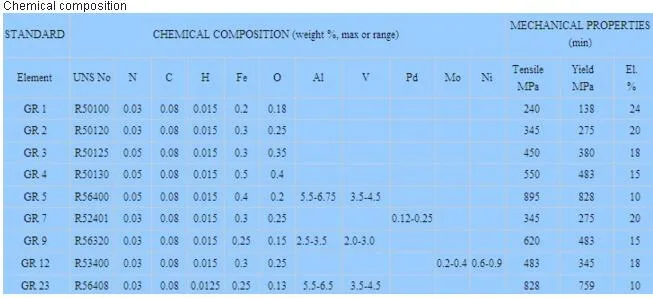

Chemical Composition :

| C | Fe | H | N | O | Ti |

|---|---|---|---|---|---|

| max | max | max | max | max | max |

| 0.1 | 0.2 | 0.015 | 0.03 | 0.18 | 99.5 |

Mechnical Properties :

| Hardness, Brinell | 120 | 120 | annealed |

|---|---|---|---|

| Hardness, Knoop | 132 | 132 | Estimated from Brinell. |

| Hardness, Rockwell B | 70 | 70 | annealed |

| Hardness, Vickers | 122 | 122 | Estimated from Brinell. |

| Tensile Strength, Ultimate | 240 MPa | 34800 psi | |

| Tensile Strength, Yield | 170 - 310 MPa | 24700 - 45000 psi | |

| Elongation at Break | 24 % | 24 % | |

| Reduction of Area | 35 % | 35 % | |

| Modulus of Elasticity | 105 GPa | 15200 ksi | In Tension |

| Compressive Modulus | 110 GPa | 16000 ksi | |

| Poisson's Ratio | 0.37 | 0.37 | |

| Charpy Impact | 310 J | 229 ft-lb | V-notch |

| Shear Modulus | 45 GPa | 6530 ksi |

Physical Properties :

| Physical Properties | Metric | English |

|---|---|---|

| Density | 4.51 g/cc | 0.163 lb/in³ |

Being the emerging leader of this field, we completely value our responsibility and work hard to supply only supreme quality Buttweld Pipe Fitting. These are used in petrochemical industries, automotive, refineries and mechanical industries. It is a perfect use for tight hold on joints and sturdy support. To cater to industry defined quality parameters these components are examined thoroughly by our quality experts upon defined parameters of quality.

Raw Material, Manufacture and Inspection

The titanium or titanium alloy fittings may be made from billets & bars (ASTM B348), plates(ASTM B265), forgings (ASTM B381), and seamless or welded pipe or tube(ASTM B861 & B862). Forging, forming, or shaping operations may be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, or by a combination of two or more of these operations. Injurious