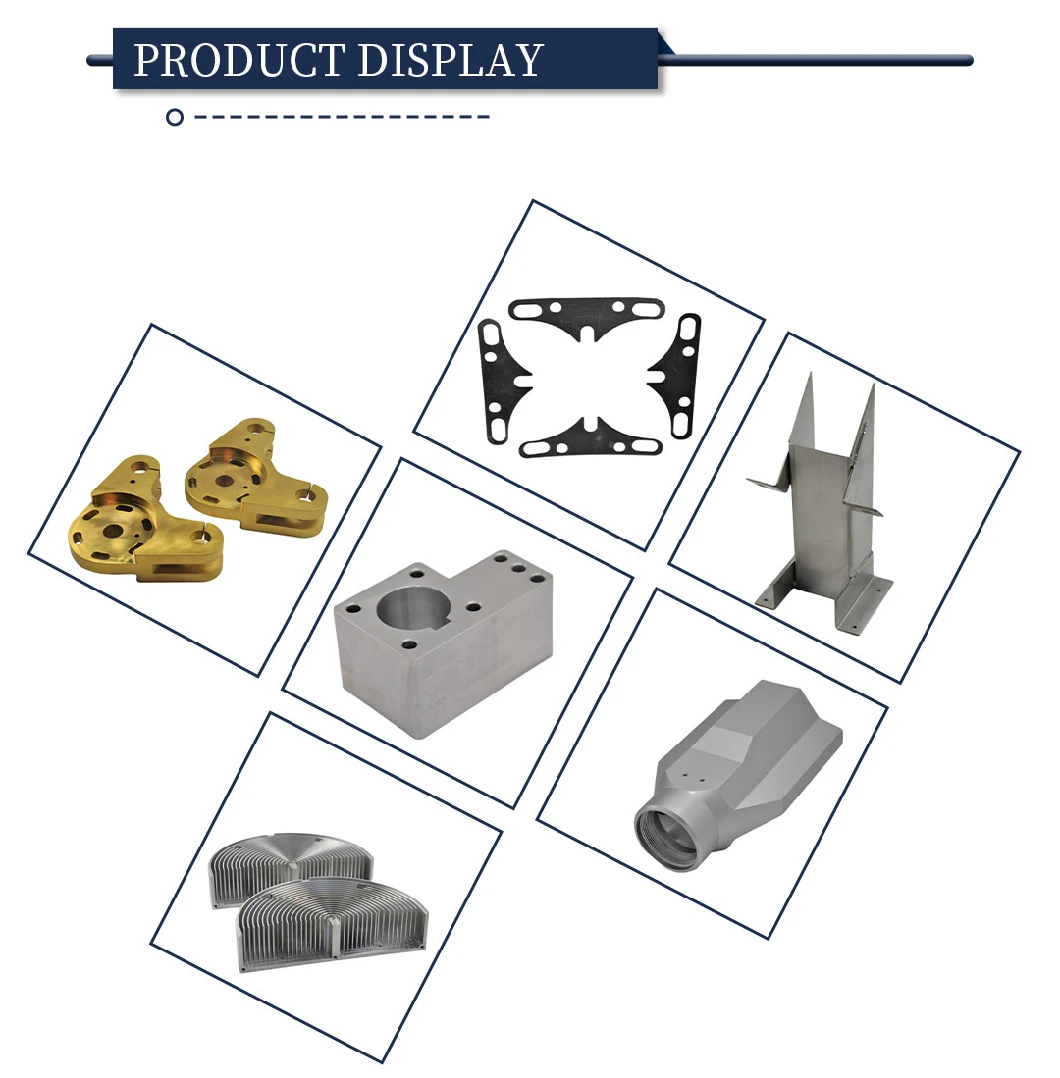

Cutting/Bending/Stamping/Punching/Welding/Assembly Processing Sheet Metal Titanium Aluminum Part

Basic Info

| Model NO. | A001 |

| Application | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

| Standard | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME |

| Surface Treatment | Anodizing |

| Production Type | Mass Production |

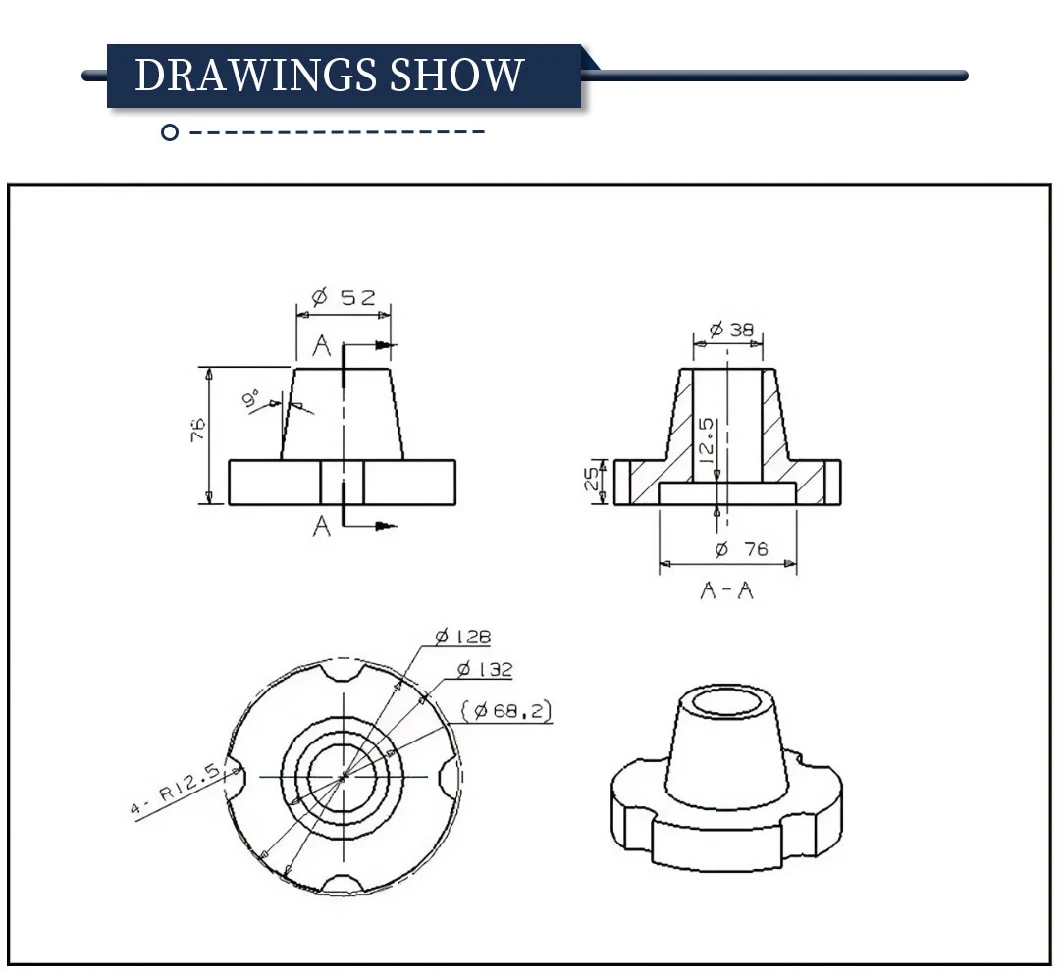

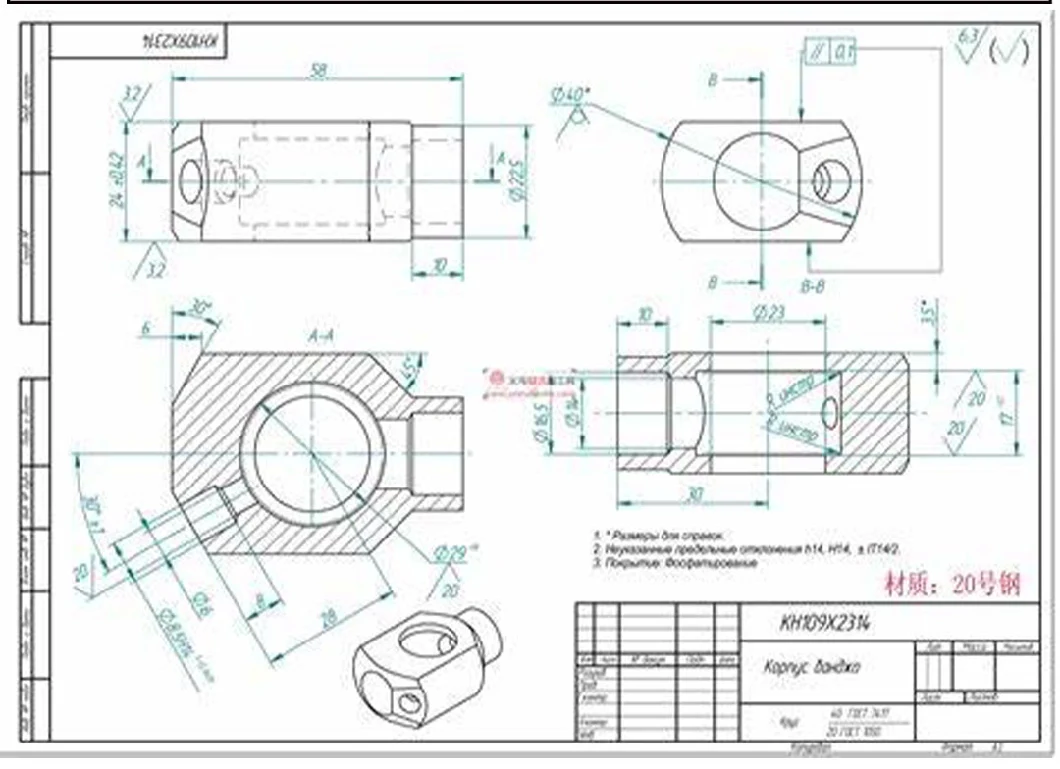

| Machining Method | CNC Machining |

| Material | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron |

| Texture | Aluminum |

| Item | OEM Precision Machining |

| Quality Control | 100% Inspection |

| Process | CNC Machining+Deburrs |

| Delivery Time | 15-25 Days |

| Transport Package | Carton Box/Plywood Box |

| Specification | OEM |

| Trademark | LUCENT |

| Origin | China |

| HS Code | 8538900000 |

Product Description

About Lucent

Lucent Ind. Manufacturing, Ltd. is Hong Kong based group company with all manufacturing facilities in Guangdong, China - Pearl River Delta area. We are specialized in manufacturing custom-made precision Machining Components, Casting Parts, Hardware, Plastic Mold Design & Build and also Production.

We offer a wide range of manufacturing solutions, including machining, casting, forging, stamping and molding. Our engineering team has rich experience in working for many Fortune 500 companies (ITW, Electrolus etc.).

We have highly skilled and experienced engineers who work collaboratively on every project. They will submit detailed manufacturing solution regarding different product's characteristics. At each manufacturing stage, our engineers work with the operation team to ensure quality control procedures are properly implemented and the specification is 100% in compliance.

We have one quality control team which is built up by rich experienced QC & QA. They will monitor each process of production. Each component or part will go through our QA for final inspection and testing. Make sure every product is under customer's requirement before reaching customers.

Our focus is to close the gap and provide lower cost manufacturing throughout the world. Sourcing your parts with Lucent MFG. is the closest thing to running your own manufacturing facility in China. We offer extreme flexibility for you and your project needs.

Capabilities

| Available Materials | ||||

| Carbon Steel | Stainless Steel | Alloy Steel | Tool Steel | Hard Alloy |

| Plastic | Aluminum | Copper | Brass | Bronze |

| Heat Treatment | ||||

| Hardening | Nitriding | Carburizing | Laser Quenching | QPQ |

| Surface Finish | ||||

| Zinc Plating | Chrome Plating | Nickel Plating | Passivation | Tin Plating |

| Silver Plating | Gold Plating | Anodizing | Hard Anodizing | PTFE Impregnated Hard Anodizing |

| Painting | Powder Coating | PTFE Coating | Brushing | Polishing |